29

2024

-

09

What's with the tolerance zone?

Source:

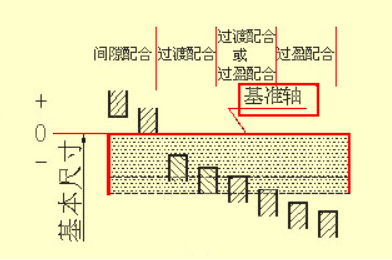

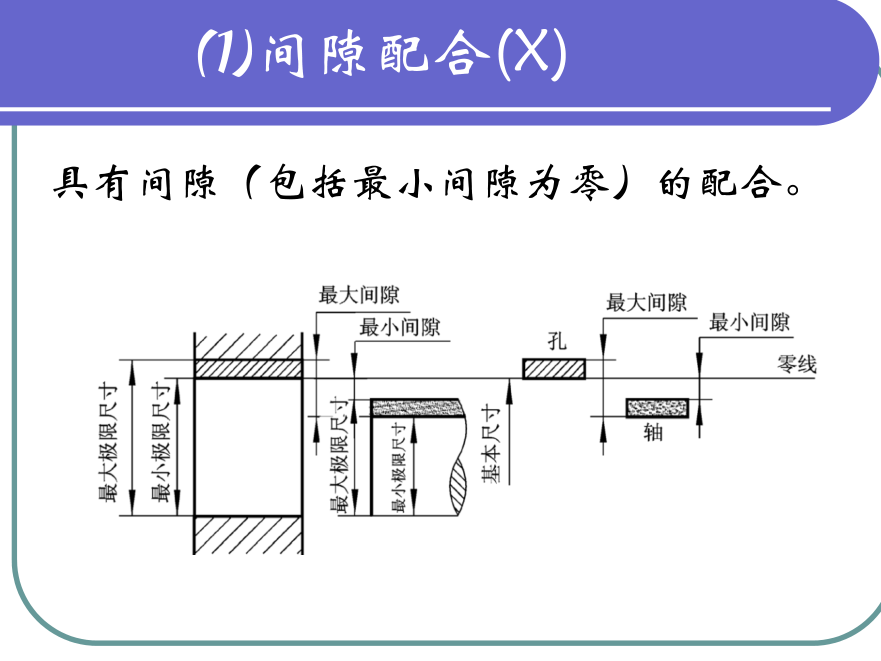

The tolerance zone is an area defined by two straight lines representing the upper and lower deviations or the maximum and minimum limit dimensions in the tolerance zone diagram. The tolerance zone includes two elements, the size of the tolerance zone and the position of the tolerance zone, the former being determined by the standard tolerance and the latter by the basic deviation.

The tolerance zone is a sequence of differences between the dimensions used in the production process and the absolutely accurate measurement.

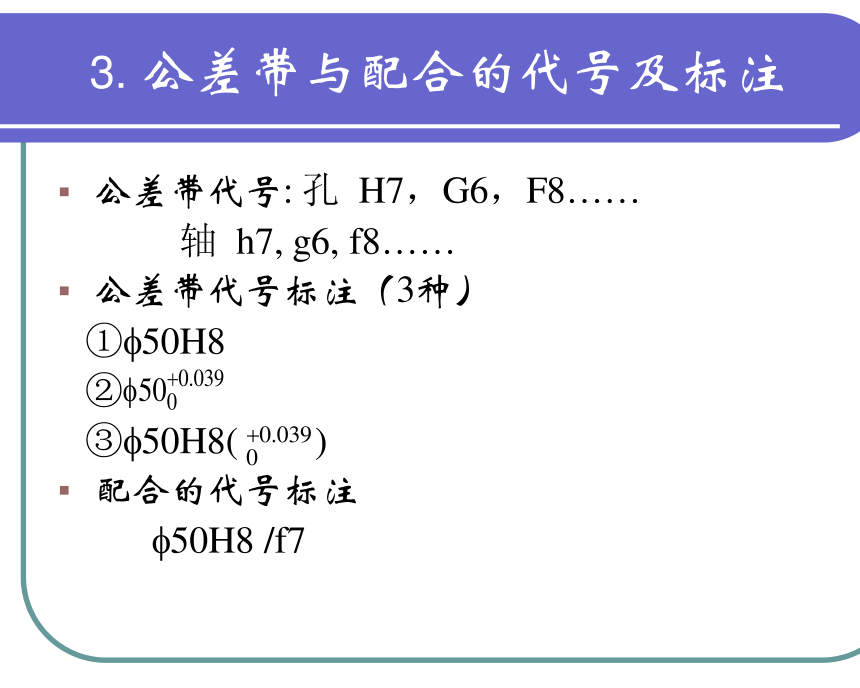

ToleranceCode name capital lettersYesHoleTolerances,lowercaseYesShaftTolerances,The smaller the number, the stricter the requirements.

Simply speaking, the narrower the tolerance zone, the higher the accuracy of processing.

Tolerance of dimension refers to the allowable variation of dimension.

The tolerance zone is used to conveniently represent the relationship between the nominal size, limit size, limit deviation and tolerance quality inspection of two combined holes and shafts. The tolerance zone is an area defined by two straight lines representing the upper limit deviation and the lower limit deviation or the upper limit dimension and the lower limit dimension in the tolerance zone, which is called the tolerance zone (or dimension tolerance zone). It is determined by the tolerance size and the basic deviation.

National Standards

Basis of Tolerance, Deviation and Fit (GB/T 1800.1-2009) There are 28 basic deviations for holes and shafts of 20 standard tolerance grades specified in the national standard. Many tolerance zones of different sizes and positions can be obtained for holes and shafts (20*27 3=543 kinds of holes and 20*27 4=544 kinds of shafts). But in production practice, so many tolerance zones will cause difficulties in production and processing. Therefore, from an economic point of view, China has made restrictions on the choice of tolerance zone.

H7/h6

H7/h6It is tolerance fit, capital letters indicate holes, lowercase letters indicate shafts, h or h indicate basic deviation, and numbers 7 or 6 indicate tolerance grade. according to the dimensions of holes and shafts, and then H7 and h6 are added, the dimensional tolerances of holes and shafts can be found in the tolerance table,

H7/g6Is a very precise base hole clearance fit. Where H represents the lower deviation of the hole, 7 is the tolerance grade of the hole, which is very close to the basic size, g represents the upper deviation of the shaft, and 6 represents the tolerance grade of the shaft, which is slightly smaller than the basic size. Since the size of the hole is slightly larger than the basic size and the size of the shaft is slightly smaller than the basic size, the two form a clearance fit.

Take the shaft with diameter Φ20 as an example, Φ20H7/g6; Look up the table:

Hole: Φ20H7 Tolerance: Φ20(+0.021/0)

Shaft: Φ20g6 Tolerance: Φ20(-0.007/-0.02)

From this, the maximum clearance and the minimum clearance can be calculated as: 0.041 and 0.007mm respectively

Question:

1Is there a difference between H7/H6 and H6/H7?

There is no h6/H7 labeling method, this is the wrong labeling method, the correct one should be H7/h6.

It is stipulated in the national standard that the matching code is expressed by the combination of the tolerance zone of the hole and the axis, the numerator is the hole and the denominator is the axis.

H7/h6It is the marking method in the assembly drawing. The matching code consists of the tolerance zone code of the matching hole and the shaft. It is expressed in fractional form, and the numerator is the tolerance zone code of the hole. The denominator is the tolerance zone code of the shaft (when using an oblique score line, the oblique score line should be highly flush with the code in the known numerator and denominator).

Extended information:

H7/h6, you can calculate the base hole system, can also calculate the base axis system. It depends on who is the benchmark and who is the benchmark match. H7/h6 has very different meanings expressed on different benchmarks, as follows:

When the hole is used as the reference, H7 is the reference hole with a tolerance level of 7, and h6 is the shaft with a 6-level accuracy and clearance fit. When the axis is used as the reference, h6 is the reference axis with tolerance level 6, and H7 is the hole with precision and clearance fit level 7.

Graphic knowledge:

Basic deviation:

The basic deviation refers to the upper or lower deviation of determining the position of the tolerance zone relative to the zero line, generally the deviation close to the zero line.

Code and label of tolerance zone and fit Code of tolerance zone: holeH7 G6 F8Shafth7,g6,f8Terror belt code marking (3species) 1:50H8 ...

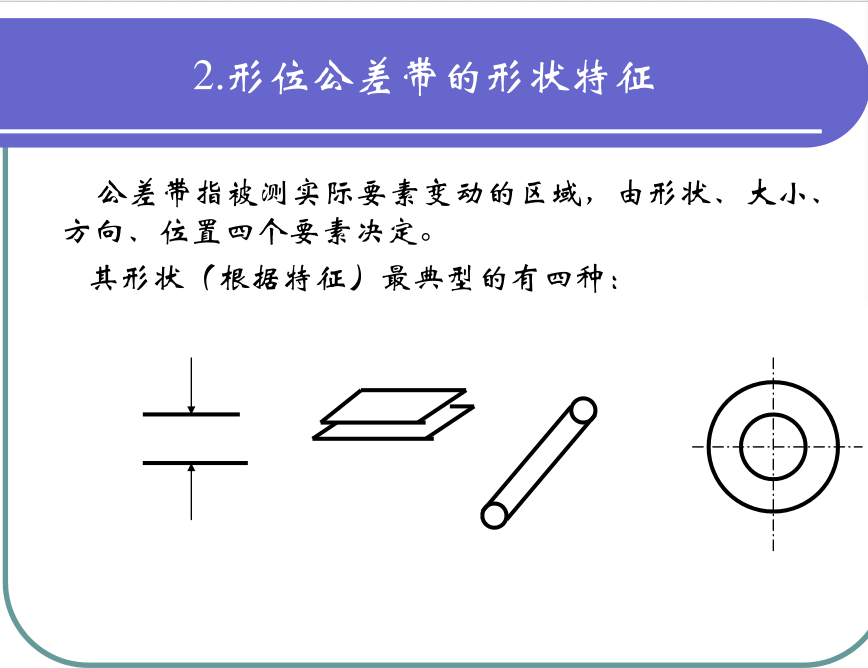

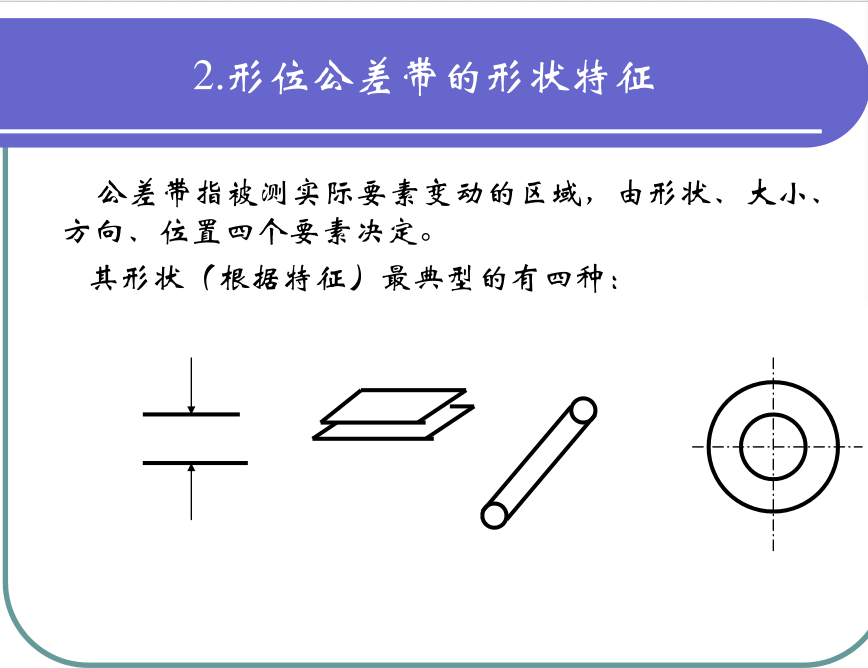

Ideal element: an element that has a geometric meaning and does not have any error.

Actual element: the element that actually exists on the part, which is replaced by the measured element during measurement, which is not the true form of the element.

The measured element: the element that gives the shape or position tolerance on the drawing, and the measured element is divided into a single element and an associated element.

Single feature: A feature that gives form tolerance requirements only for itself.

dWhen the cylindrical surface rotates around the reference without axial movement, the radial runout in any measurement plane shall not be greater than the tolerance value.0.05mm.

Note: Common grade is in black box and basic grade is in brackets.

Note: Common grade is in black box and basic grade is in brackets.

Related Articles

Sweep the mobile phone browsing

Contact Us

International sales manager: John Mob: +8618539115199

Email: xydgbcn@gmail.com

Add: Gutuo Village, Chengliu Town, Jiyuan City, Henan Province

©2022 Jiyuan Xinyang Metal Chrome Rod Co., Ltd. Copyright All Rights Reserved Website Supports IPV6